Contract Crushing, or as some people call it “Custom Crushing”, is a service that has solved many problems for aggregate producers over the past multiple decades. Whether it is opening a greenfield site, gaining added salable inventory through supplemental crushing, recycling asphalt or concrete, or the myriad of other needs, Mellott has implemented many solutions for customers utilizing Contract Crushing. In fact, Contract Crushing has been the heart and soul of our organization since the 1970s. We’ve partnered with small family-owned operations, we’ve helped build aggregate producer empires, and everything in between. Mellott’s contract crushing division has reached an unparalleled level of excellence in providing solutions to our producer customers in areas such as:

Wear Protection Materials

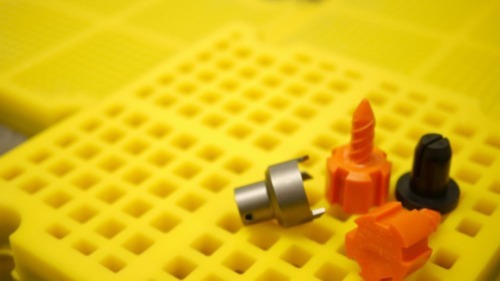

There are a number of materials that can be used for wear prevention in rock-crushing equipment. The most important factor is to select the right material for the specific application. Some of the most common materials include:

Manganese

These alloys are designed to be applied as a coating to wear surfaces. They are typically composed of high-quality steels and are available in a variety of different grades to suit different applications. Mellott has a team of Application Engineers with decades of experience that are armed with the latest technology to determine the right liner profile and metallurgy that suits your crusher’s needs.

Once Mellott has determined the best profile for your crusher, we can help to supply those liners. Mellott offers OEM and aftermarket manganese wear liners that fit Metso, Eagle, Lippman, Superior, Cedarapids, JCI, KPI, Telsmith, Sandvik, Pegson, Extec, and more. Our vast inventory of mantles, bowl liners, jaw dies, concaves, blow bars, anvils, shoes, and more are available in 11-14%, 18% and 22% alloys.

Screen Media

Polyurethane provides a superb wear life, noise reduction capabilities, flexibility to prevent blinding and pegging, and an ease of installation that proves its one of the safest media options out there. Along with polyurethane, wire mesh and rubber media are options too.

Reduce risk and minimize exposure with some of the industry’s most popular, safe, high quality and environmentally friendly products. Mellott offers an array of these products including polyurethane, rubber, and wire screen media. These vary from magnetic opencast polyurethane panels to hammerless injection molded polyurethane 1×1 panels.

Wear Protection Liners

Polyurethane liners are another versatile option for wear prevention. They can be used in a variety of applications, and offer good protection against both abrasive and impact damage. Mellott offers a multitude of liners for any area where materials flow including Chute Liners, Magnetic Liners, Pan Feed Liners, Cross Member Protections, Curved Application, and more.

Tips For Minimizing Wear

In order to protect your equipment that is being used, it is important to take measures to prevent wear and tear. There are a few things that can be done to achieve this:

The first step is to make sure that the equipment is properly sized for the job. If it is too big or too small, it will put unnecessary stress on the machinery.

Secondly, proper maintenance and lubrication are essential. This includes managing the amount of debris, as well as making sure that the oil levels are adequate.

Finally, operators should be aware of how to use the equipment to the best of its ability. For example, knowing when to replace the manganese can not only save downtime, but also money. Wear products will need to be replaced and getting to this sooner rather than later is key.

Achieve Optimal Wear Protection With Mellott

Working with a professional rock-crushing company guarantees that the proper protection practices will be followed. At Mellott, we understand the importance of proper wear protection. We can help any size organization to maximize their wear protection protocols and ensure they are maximizing the value of their investment towards equipment. This is important because failing to properly protect equipment can result in excessive wear and even failure. The benefits of working with us include:

- Expertise: We have the expertise to protect your equipment from wear. We have a deep understanding of the latest and most effective wear protection practices.

- Experience: We have years of experience in protecting equipment from wear. Let us put our skills to work for you and help you simplify this process.

- Compliance: We will ensure that all safety and compliance regulations are followed.

For more information on how we can help you enact an efficient wear protection system within your operations, reach out to our team today at (855) 554-1606.

"*" indicates required fields